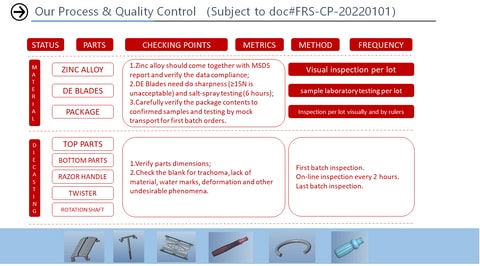

We have a clear and strict quality control plan during each process

At Guangzhou Color Fans Beauty Tools Co., Ltd., the journey of creating exceptional beauty tools is rooted in a rigorous quality control process that ensures each product not only meets but exceeds industry standards. Our commitment to excellence is evident in every step of our manufacturing process, from initial design to the final product that reaches your hands.

Diecasting: The Foundation of Precision

Most of our metal parts begins with diecasting, where molten metal is meticulously shaped to form the intricate components of our beauty tools. This stage sets the tone for the quality and precision of all subsequent steps.

CNC: Go beyond Precision

In the world of personal grooming, the quality of a razor can make all the difference. For manufacturers, the challenge lies in producing a razor that not only meets the functional demands of shaving but also the aesthetic and tactile preferences of consumers. This is where CNC (Computer Numerical Control) machining comes into play, offering unparalleled precision and versatility in manufacturing.

CNC machining is a subtractive manufacturing process where computer-controlled machine tools create intricate parts with a level of precision that manual operations cannot match. This process is crucial for producing razor components that require exact specifications for optimal performance and user experience.

The materials used in CNC machining for razors are as diverse as the needs they fulfill. Brass, aluminum, stainless steel, titanium, wood, resin, and bamboo are just some of the materials that can be shaped into elegant and durable razor parts. Each material brings its unique properties to the table—brass and aluminum for their malleability, stainless steel and titanium for their strength and corrosion resistance, and wood, resin, and bamboo for their natural beauty and warmth.

Behind every successful CNC machined razor part is a team of experienced engineers. These professionals ensure that every product not only meets but exceeds customer expectations in both structure and appearance. The engineering expertise involved in CNC machining allows for the creation of razors that are not just tools but works of art.

The benefits of CNC machined safety razors are manifold. They offer superior craftsmanship, with each component crafted to perfection, ensuring a close and comfortable shave. Durability is another hallmark of CNC machined razors, with high-quality materials and strict quality control measures resulting in a product that can withstand the rigors of daily use. Moreover, the enhanced shaving experience provided by these razors, with their ergonomic design and precise blade alignment, makes them a favorite among consumers seeking a premium grooming experience.

CNC machining has revolutionized the manufacturing of razor parts, offering a level of precision, durability, and beauty that elevates the shaving experience. As the demand for high-quality personal grooming products continues to grow, CNC machining stands as a testament to the fusion of technology and craftsmanship in the pursuit of perfection.

Machining: Sculpting with Accuracy

Following diecasting, machining refines the components, sculpting them with unparalleled accuracy. Our skilled technicians ensure that each piece meets precise specifications, laying the groundwork for flawless functionality.

Polishing: The Art of Aesthetics

Polishing transforms the raw metal into a work of art. It's here that the visual identity of our products comes to life, with each piece receiving a high-gloss finish that speaks to our aesthetic values.

Electroplating: Enhancing Durability

Electroplating is not just about achieving a beautiful sheen; it's also about enhancing the durability of our products. We conduct a 100% inspection before and after this process to guarantee that each item is resistant to wear and corrosion.

Assembling: Meticulous Integration

Assembling is a testament to our attention to detail. Each component is carefully integrated, ensuring seamless operation and a user experience that reflects our brand's promise of quality.

Packing: The Final Touch

Our packing process is the final touch in our commitment to excellence. We ensure that each product is securely packaged, ready for a safe journey to customers worldwide.

Shipping: Delivering Satisfaction

Shipping marks the end of our manufacturing journey but the beginning of customer satisfaction. We take pride in delivering our products promptly and efficiently, no matter the size of the order.

Quality Assurance: Beyond the Basics

Quality assurance at Guangzhou Color Fans goes beyond the basics. Salt spray and drop testing are conducted monthly on random batches to ensure our products withstand the test of time and use.

We understand that challenges can arise in any process. That's why we have robust procedures in place to address temporary issues swiftly, ensuring that our production line remains uninterrupted and our quality uncompromised.

At Guangzhou Color Fans, every piece of metal, no matter how small or large the batch, receives our undivided attention. Our promise is perfection, and our processes are designed to deliver just that.

We invite you to experience the difference that our dedication to quality makes. Visit our website to explore our range of beauty tools and join us in celebrating the art of beauty.

For more information on our products and processes, or to place an order, please contact us. We look forward to serving you with the excellence you deserve.